Nice Compressors Company manufactures air compressor with a huge range of Air Compressors, Vaccum Pumps and its spare parts. It has developed and innovated the compressed air systems by sustainable efforts.

These products are used in daily activities in painting, engineering, wooden industry, hospitals and pharma industries, cement and constructions, pneumatics applications and many others.

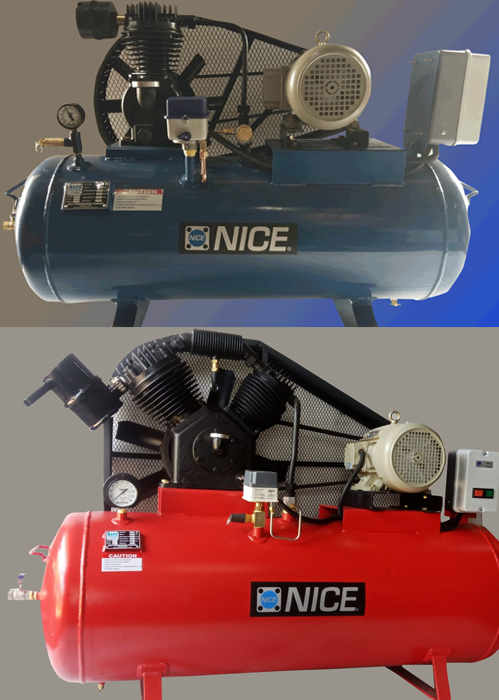

Nice Compressors Company offers a wide range of compressed air products from single stage, double stage, high pressure air compressors to large variety of oil free compressors and vaccum pumps..

Nice Compressors Company has expertise and dedicated professionals who assures technically ensures strict adherence to quality measures so as to deliver quality products & services to the delight of our customers.

Nice Compressors Company manufactures air compressor with a huge range of Air Compressors, Vaccum Pumps and its spare parts. It has developed and innovated the compressed air systems by sustainable efforts. The continuous R&D process has helped in achieving the superior quality at minimum and low cost of products. Nice Compressors Company offers a wide range of compressed air products from single stage, double stage, high pressure air compressors to large variety of oil free compressors and vaccum pumps.

Read MoreWe are are manufacturing Single stage air compressor is a compressor where an air is sucked by inlet valve by way of single & double cylinder and discharges from the other side of block in the air receiver.

At Nice Comp company we are manufacturing the Two stage compressors are rugged packages for use either as a total air system for small industrial installations or a backup system in major installation.

We can provide a complete turnkey system for almost any high pressure air demand. For special requirements, we can modify a standard package or design a custom package specific to the customer’s needs.

Air receivers are essential to every compressed air system. They act as a buffer and provide storage for short periods of high demand. Receivers reduce compressor cycling and improve system performance.

Single stage compressors are rugged packages for use either as a total air system for small industrial installations or a

backup system in major installation.• Air Receiver as per ESMA standards Hydraulically and Pneumatically tested at 20 kg/cm2.

The main difference between single and two stage compressors is the number of times that air gets compressed between the inlet valve

and the discharge Valve. In a single stage compressor, the air is compressed one time; in a two stage compressor, the air is

compressed twice to double the pressure

Our Client Testimonials

Very easy to locate and buy an air compressor of the requirements I needed. Quick response from the Nice Compressor team and the entire experience was good.

I am very much thankful to Nice Compressor for the advice they gave us on required compressor as per our machines. The air audit and advice on piping was equally very helpful.

Initially I was confused regarding the size of a compressor for painting application. Nice Compressor guided me technically and suggested me as per my requirement and i really thank them. .

Our superior quality is the primary reason behind our immense success in the market. We, at Nice Compressor maintain the best standards of quality at every stage of our product process. The carefully selected raw materials are sourced from the most reliable vendors of the market. Every work is executed by an experienced team of technically proficient engineers having extensive knowledge in their respective discipline.

A well equipped facility, ultra modern technology and a team of best engineers themselves narrate the saga of our robust infrastructural abilities. We employ state-of-the-art machines in our process that facilitate efficient and smooth production. Nice Comp has in-house facilities for designing, production and quality control to execute every task efficiently.We spend significantly in the areas both technical and employee programs.

Nice Compressor invite queries of our valued Indian & overseas customers for further clarification. Nice Comp have developed real depth and breadth of engineering skills and processes. The empirical innovations without the limitation typically found in a development environment have allowed us to deliver low-cost and rapid solutions in Air Compressor, Vaccum Pumps and its spare parts.

Air compressor is a device that converts power (usually from an electric motor, a diesel engine or a gasoline engine) into kinetic energy by compressing and pressurizing air, which, on command, can be released in quick bursts.

In a rotary screw compressor, oil should be changed about every 7000-8000 hours. This depends on the type of compressor you purchase. For a Reciprocating air compressor, generally you would change the oil approximately every 3 months.

The tank size you will use will depend on the amount of air that you need stored. A benefit to bigger tanked air compressors is that the motor will not start and stop as often as a smaller tanked compressor.

This depends on how often you run your compressor. If you are running your compressor rarely, then annual service would be fine. If you are running your compressor routinely, then quarterly service may be needed.

Read More - FAQ